Duplex Stainless steel

2304 stainless steel is a duplex stainless steel that offers a balanced combination of austenitic and ferritic properties, providing good strength and corrosion resistance. It is particularly effective against stress corrosion cracking in chloride environments and has better resistance to corrosion than standard ferritic grades. 2304 is more cost-effective than higher alloyed duplex grades and is commonly used in applications such as tanks, heat exchangers, and piping systems in chemical and petrochemical industries. Its good weldability makes it suitable for various fabrication processes.

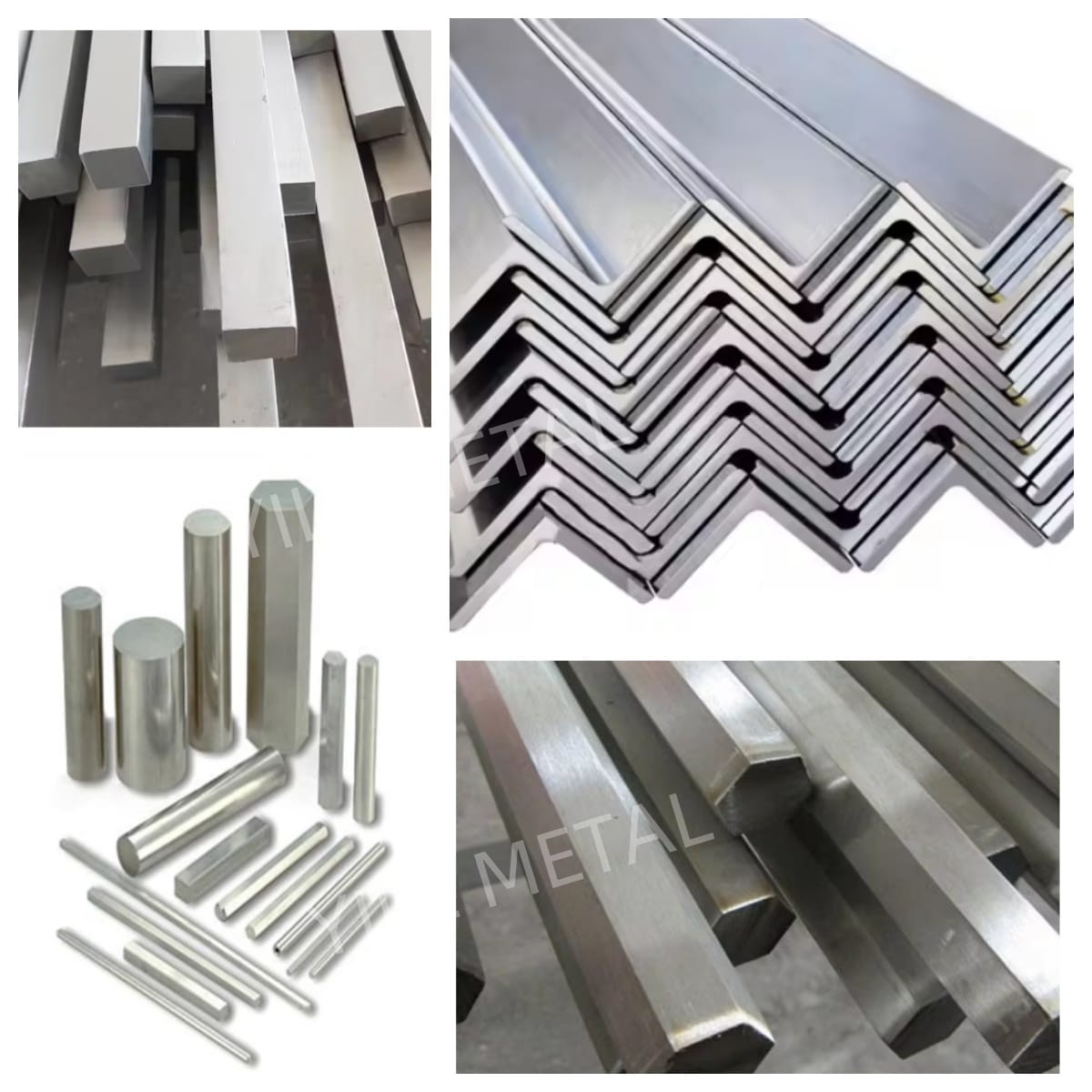

Product Description:

| Standards: | ASTM A276, GB,ASTM,ASME,EN,JIS,DIN,BS,ISO |

| Grade : | 200series: 201J1,J2,J3,J4 202, 202cu, 204; 300series: 301, 302, 303, 304, 314,304L, 309, 309s, 310, 310S, 316, 316L, 316Ti, 317L, 321, 347; 400series: 409, 409L, 410, 410S,420, 430, 431, 440A,440B, 440C; Others: 330, 660, 630, 631, 17-4ph, 17-7ph, S31803 ,904L, etc. Duplex : (S31803, S22053, S25073, S22253, S32205, S32304; 2205, 2507) And others etc… |

| Surface: | Black, Bright, Polished, Peeled, |

| Diameter: | 4-500mm |

| Length : | 2500mm,2900mm,5800mm,6000mm&Customized. |

| Tolerance: | As per standard ISO |

| Shape: | Round, Square, Hex, Rec,Flat etc. |

| End: | BE,PE, Chamfering. |

| Processing: | HR,CR,Forged, Cold Drawn, Precision etc |

| Loading Port: | Shanghai or any port in China. |

| Packing: | Bundled,wooden box , seaworthy packing or Customized. |

| Payment Term: | T/T , LC, Credit Card, other negotiable |

| Trade Terms | EXW, FOB,CFR,CIF,FCA,CPT,DDU etc. |

| MOQ | 1000kgs Customized Products |

| Delivery time | 7-25days based on processing and stocks. |

Type of Stainless Steel:

Stainless steel is divided into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and duplex stainless steel according to the structure state.

Austenitic Stainless Steel

stainless steel with an austenitic structure at room temperature. Steel contains Cr≈18%, Ni≈8%-25% and C≈0.1%. Steel has high toughness and plasticity, but low strength.

Martensitic Stainless Steel

A steel whose mechanical properties can be adjusted by heat treatment. It has different strength and toughness at different tempering temperatures.

Duplex Stainless Steel

Austenitic and ferrite each account for about half of the structure. When the C content is low, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some steels also contain alloying elements such as Mo, Cu, Si, Nb, Ti, and N. This type of steel has the characteristics of austenitic and ferritic stainless steel

Ferritic Stainless Steel

It contains 15% to 30% chromium and has a body-centered cubic crystal structure. This type of steel generally does not contain nickel, and sometimes contains a small amount of Mo, Ti, Nb and other elements. This type of steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance.

| Austenitic Stainless Steel | 201, 301, 304, 305, 310, 314, 316, 321, 347, 370, etc |

| Martensitic Stainless Steel | 410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc |

| Duplex Stainless Steel | S31803, S32101, S32205, S32304, S32750, etc |

| Ferritic Stainless Steel | 429, 430, 433, 434, 435, 436, 439, etc |

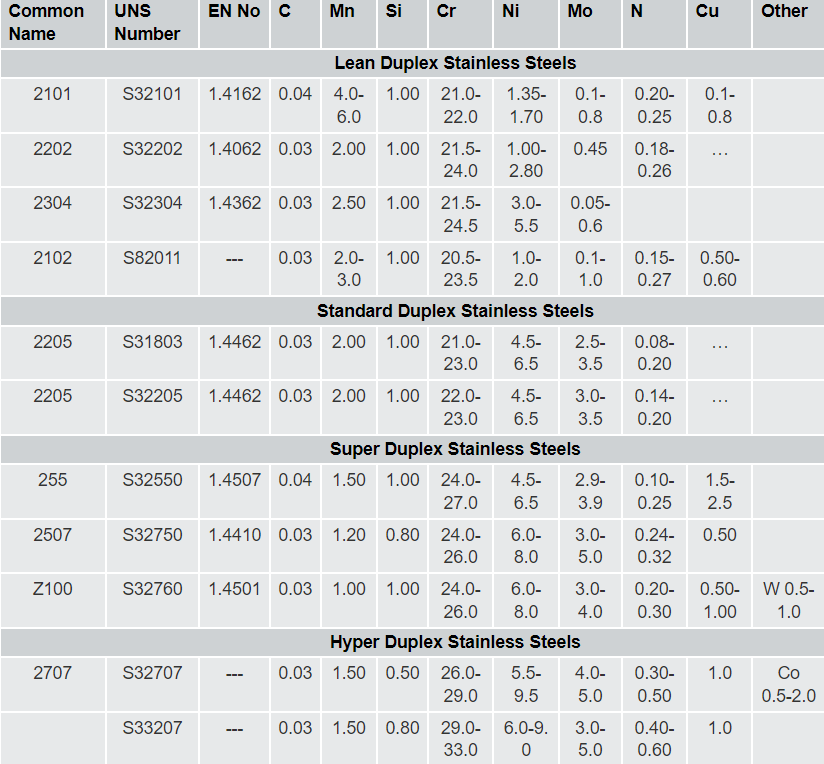

Chemical Composition of come common Duplex stainless steel

Product Presentation:

Packing:

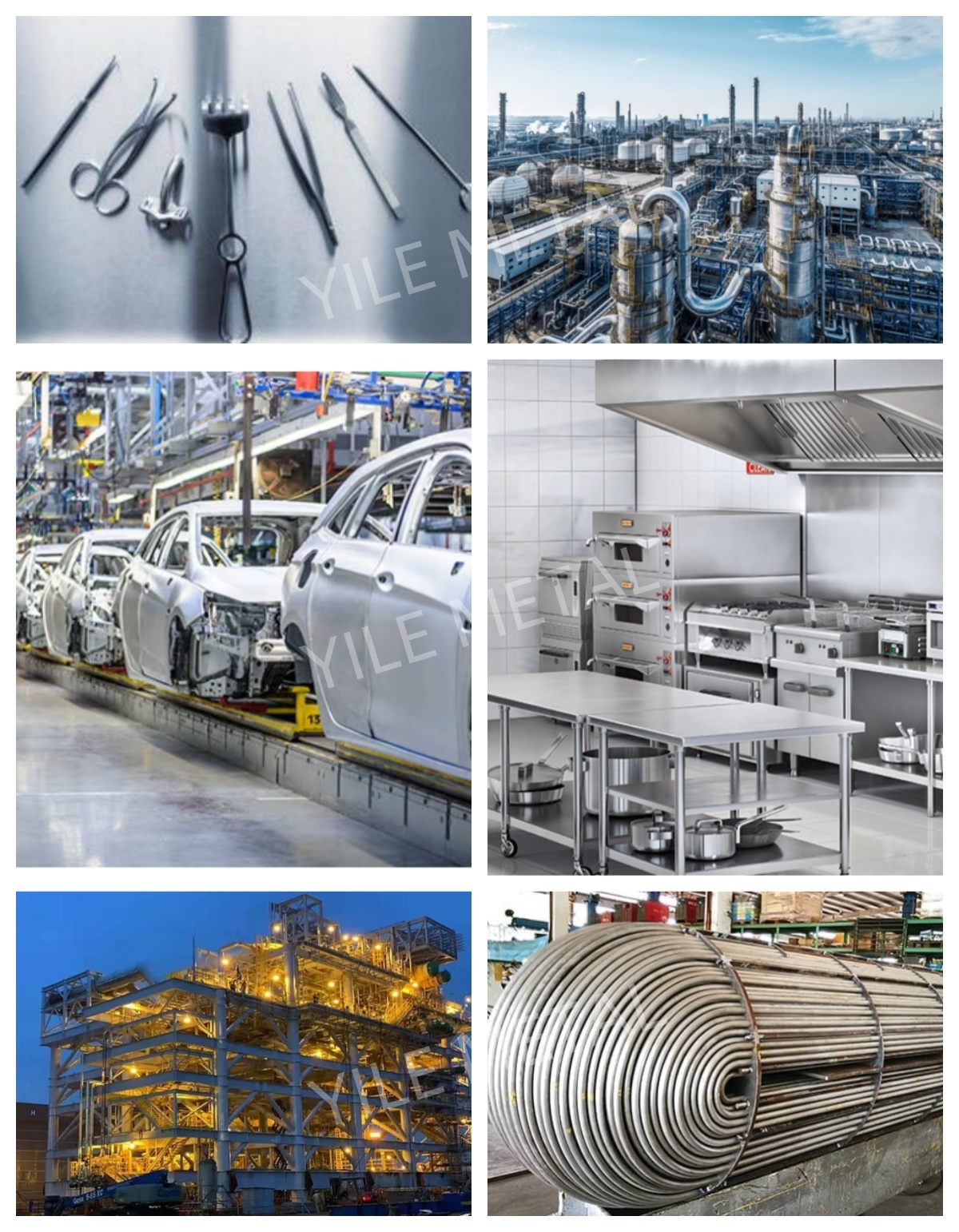

Application:

Stainless steel profiles are widely used across various industries and fields due to their excellent corrosion resistance, strength, workability, and aesthetic appeal. Below are the main uses of stainless steel profiles:

1. Construction and Structural Applications

2. Industrial and Mechanical Manufacturing

3. Automotive and Transportation

4. Medical Equipment and Food Processing

5. Household and Consumer Products

6. Energy and Power

Why us?

You may be tired of searching for suppliers in China. Why not stop and give us a chance to speak with quality and start our journey of trust with a trial order.

YILE METAL CAN NOT breath without Quality!